The Evolution of In-Mold Decorations in Production Processes

The Evolution of In-Mold Decorations in Production Processes

Blog Article

Grasping In-Mold Decorations: Techniques, Fads, and Finest Practices for Optimal Outcomes

In the realm of production, the art of in-mold decorations stands as a critical element of product layout and manufacturing. In-Mold Decorations. By diving into the methods, fads, and finest practices that underpin successful in-mold design procedures, companies can unlock a realm of possibilities that not just boost the visual appeal of their products yet additionally streamline production effectiveness and bolster consumer interaction.

Product Choice

Product choice is a crucial aspect of mastering in-mold decorations, as it straight impacts the high quality and resilience of the end product. When choosing products for in-mold decors, it is necessary to take into consideration variables such as compatibility with the molding process, the preferred visual result, and the environmental problems the product will face. Polycarbonate products like polypropylene, abs, and polycarbonate are typically used for in-mold decorations as a result of their versatility and capability to achieve elaborate styles. These products offer superb moldability, allowing makers to produce intricate forms and patterns with precision.

Additionally, materials with high heat resistance are liked for in-mold designs, particularly for products that will be revealed to elevated temperature levels throughout their lifecycle. By meticulously choosing the suitable product for in-mold designs, makers can enhance the overall quality and longevity of their items, meeting the expectations of both end-users and customers - In-Mold Decorations.

Design Advancement

An essential element in advancing the area of in-mold designs is the continuous exploration and implementation of design development techniques. Style advancement plays a crucial duty in improving the visual appeal, capability, and general top quality of products produced using in-mold decoration procedures. By including ingenious style aspects, makers can separate their products on the market, bring in consumers, and stay in advance of competitors.

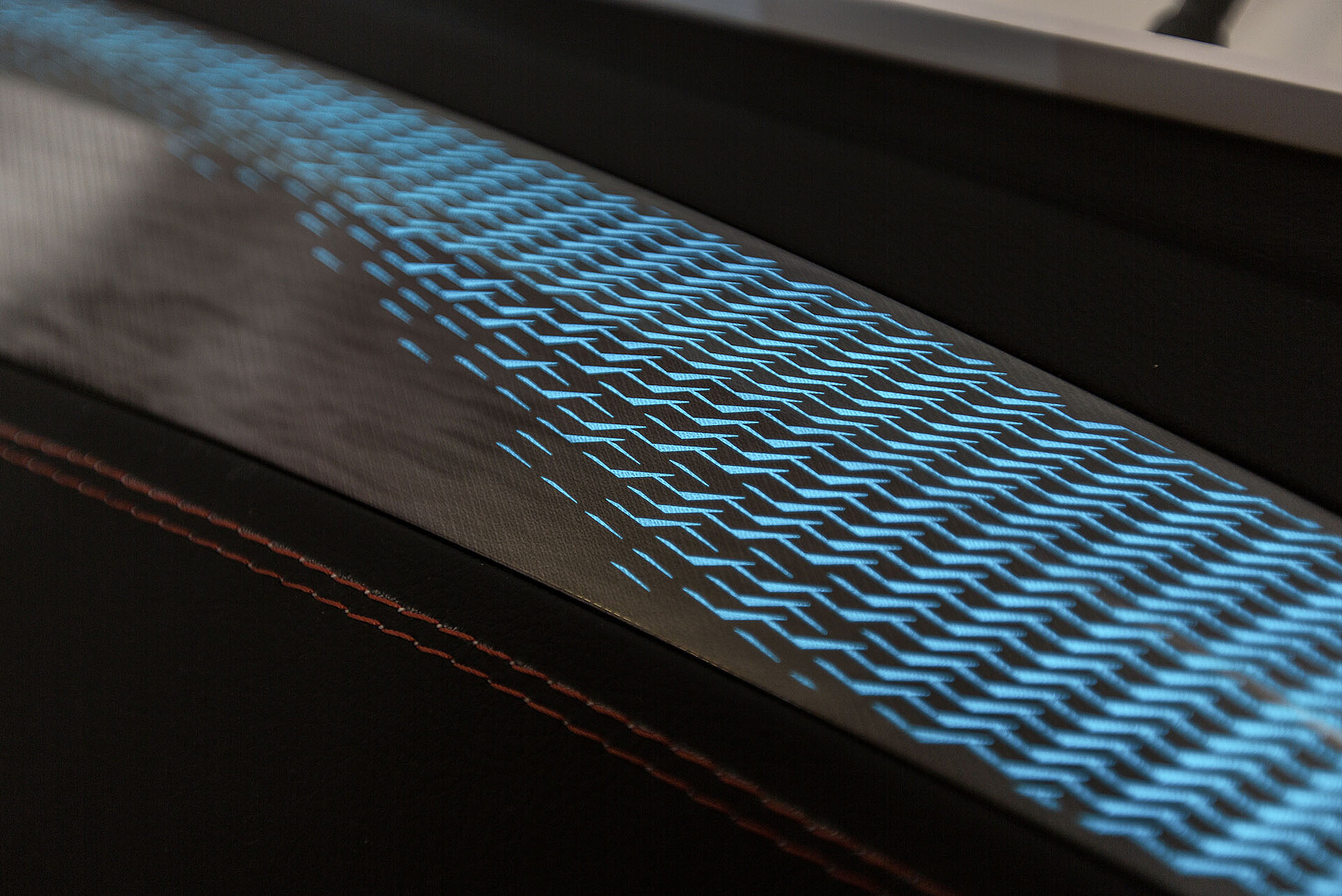

One of the essential elements of design innovation in in-mold designs is the assimilation of complex patterns, textures, and graphics that were previously challenging to achieve with traditional design techniques. Advanced innovations such as 3D printing and electronic design devices enable designers to create complex and detailed designs that can be seamlessly moved onto molded parts. Furthermore, using vibrant shades, metal coatings, and unique effects like gloss or matte appearances can even more raise the aesthetic appeal of in-mold embellished items.

Additionally, design innovation extends past aesthetics to include useful improvements such as ergonomic forms, incorporated attributes, and customizable components that provide to details individual requirements. By embracing layout advancement, manufacturers can open new possibilities for imagination, personalization, and item distinction in the competitive landscape of in-mold decors.

Manufacturing Performance

Effective production procedures are essential for equating the ingenious layouts established in the area of in-mold decors into high-quality finished items that satisfy market demands and customer assumptions. In the world of in-mold designs, manufacturing efficiency includes various essential aspects that add to the overall success of the manufacturing procedure. One crucial aspect is the optimization of mold and mildew layout and tooling to make certain smooth and specific decoration transfer onto the last product. By fine-tuning mold arrangements and buying high-quality tooling materials, makers can improve efficiency and uniformity in production.

In addition, applying automation and robotics in the assembly line can substantially enhance efficiency by simplifying repeated tasks and minimizing the margin of error. Automation not just increases the manufacturing process but additionally boosts accuracy and repeatability, leading to a more uniform and high-grade output. Additionally, taking on lean manufacturing principles, such as just-in-time supply monitoring and waste decrease methods, can further enhance manufacturing performance by decreasing downtime and enhancing resource use. Overall, an all natural approach to production effectiveness is critical in taking full advantage of the possibility resource of in-mold decoration strategies and attaining ideal results in the affordable market landscape.

Quality Assurance Actions

What are the essential strategies for ensuring stringent quality assurance actions in the realm of in-mold decorations? Quality control steps are critical in in-mold design procedures to guarantee the manufacturing of remarkable and top notch completed products. One essential strategy is the application of rigorous inspection procedures at every phase of the production process. This entails performing thorough aesthetic inspections, dimensional checks, and shade uniformity assessments to determine any variances or defects early on.

Making use of advanced modern technologies such as automated assessment systems can also enhance the quality assurance process by offering accurate and reputable data for evaluation. These systems can find imperfections that might be missed out on by hands-on inspections, consequently enhancing total product top quality and consistency.

Routine training and development programs for employees associated with the in-mold design procedure can likewise add to maintaining high-quality criteria. By educating staff on ideal practices, top quality assumptions, and the significance of interest to detail, firms can foster a culture of top quality consciousness throughout the organization.

Consumer Appeal

To boost the bankability of in-mold decor items, understanding and providing to consumer choices play a vital function in identifying their allure and success. Supplying modification alternatives such as tailored styles, color variants, and textural components can dramatically boost the appeal of in-mold decor products.

Final Thought

In-mold decorations use a flexible and reliable method to improve item aesthetic appeals. By thoroughly picking products, welcoming innovative styles, maximizing production procedures, applying top quality control measures, and prioritizing customer allure, producers can achieve optimum outcomes. It is crucial for firms to continuously adapt and improve their methods to remain affordable in the market. In-Mold Decorations. Mastering in-mold designs calls for a holistic strategy that considers all elements of the manufacturing process to ensure success.

In the realm of manufacturing, the art of in-mold decorations stands as an essential facet of item layout and production. Layout development plays a crucial role in enhancing the visual charm, functionality, and general high quality of products manufactured making use of in-mold design procedures.One of the essential elements of style technology in in-mold designs is the integration of intricate patterns, appearances, and graphics that visit their website were formerly challenging to accomplish with standard decoration methods.Effective production procedures are crucial for equating the cutting-edge designs established in the field of in-mold designs into top notch ended up items that satisfy market needs and consumer expectations. Providing customization options such as tailored layouts, color Visit Website variations, and textural components can considerably improve the allure of in-mold decor items.

Report this page